Anti-lock Braking System (ABS)

Anti-lock Braking System (ABS)

Anti-lock Braking System (ABS)

Abstract

Antilock

Braking System (ABS) is used in advanced automobiles to stop slip and locking

of the wheel when brakes applied. It is an automobile safety system, the controller is

provided to regulate the necessary torque to maintain optimum slip ration. The

slip ration denotes in terms of vehicle speed and wheel rotation. It’s an

automatic system that runs on principles of threshold braking and tempo braking

which were practiced by skilled drivers with a former generation braking system.

Its reaction time is extremely faster in order that makes easy steering for the

driving force. ABS classically offer generous vehicle control and minimalize

the stopping distance in the slippery and dry surface, conversely on loose surface

like grit or snow-covered roadway, ABS can meaningfully increase braking

distance, even though still improving vehicle control.

INTRODUCTION

Antilock braking

system (ABS) prevents brakes from locking during braking. In usual braking condition

the driver alteration the brakes, but during severe braking or on slippery roads

when the driver the wheels to approach lockup, the antilock takes over here. The

ABS tempers the brake line pressure autonomous of the pedal force to carry the

wheel speed back to the slip level range that necessary to the optimal braking

performance. The ABS does not let full wheel lock in braking. In simple terms,

during the emergency of braking, the wheel does not get locked even if you push a

full auto pedal and hence the skidding does not take place. It allowed drivers

to regulate the car easier, even on roads with low adhesion, such a rain, snow, and muddy road. The mind of the antilock braking system contains Electronic Control

Unit (ECU), wheel speed instrument, and hydraulic modulator. ABS may be a loop;

hence it used the feedback control system that modulates the brake pressure in

response to the wheel deceleration and wheel angular velocity to prevent the

controlled wheel from locking.

SUBSYSTEM OF ANTILOCK BRAKING SYSTEM (ABS)

Wheel-Speed Sensors

All of the ABS wheel speed sensors notice the

speed of the corresponding wheel. The sensor consists of an enduring magnet,

coil, and tonewheel. The magnetic flux produced by the permanent magnet changes

as each tooth of the tone wheel (which rotates together with the wheel) passes

in front of the magnet’s pole piece. The altering magnetic flux induces

voltages at a frequency reliable to the wheel speed.

Electronic Control Unit (ECU)

The effort of

ECU is to obtain, amplifies, and filters the sensor signals for calculating the

speed rotation and acceleration of the vehicle. ECU also uses the speeds of two

slantwise conflicting wheels to analyze an approximation for the speed of the

vehicle. The slip of every wheel is obtaining by comparing the reference speed

with the individual wheel. During wheel slip or wheel hastening condition

signal server to attentive the ECU. The minicomputer is aware by sending the

trigger the pressure switch valve of the solenoids of the pressure modulator to

modulate the brake pressure in the distinct wheel brake cylinders. The ECU

reacts to a documented defect or error by switching off the broken part of the

system or shutting down the whole ABS

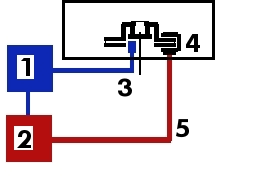

Hydraulic Pressure Modulator/ Hydraulic Control Unit

The Hydraulic

pressure modulator is an electro-hydraulic expedient for plunging, reinstating, and land the pressure of the wheel by working the solenoid valve within the

hydraulic brakes system. ABS hydraulic modulator component contains the valve,

solenoid, and piston. Under the hard braking condition, this assembly controls the

holding and release of the various hydraulic brakes circuit. Throughout the

normal condition, the normal braking system used. Whenever a hard braking condition

occurs, the system senses the change in the revolution of the speed sensor and

decides whether to grip or release pressure to a brake circuit. A tire has its

best traction just before it begins to skid, once it begins to skid a portion of

traction and steering will be lost.

ANTI-LOCK BRAKE TYPE

Different

schemes of anti-lock braking system use depending upon the types of brakes use.

Contingent upon the channel (valve) and number of speed sensors the antilock brake

is classified.

Four Channels, Four Sensors ABS

It is a better

type, the speed sensor on all the four wheels and contain a separate valve for

all four wheels. By exhausting this setup, the controller monitors each wheel separately

to make sure it is attaining an all-out braking force.

Three Channels, Three Sensors ABS

This type of system is can be found commonly in the pickup trucks with four wheels ABS, on each of the front wheels there's a controller and a speed sensor, and one controller and one sensor for both rear wheels. The speed sensor for rear wheels is found within the rear axle. To attain the all-out braking force, this system delivers separate control to the front wheels. The rear wheels, however, are controlled together; they are both have to start to padlock before the ABS will active on the rear. With the help of this system, it's possible that one of the rear wheels will padlock throughout a stop, dipping brake effectiveness.

One Channel, One Sensor ABS

This Preparation can be seen in pickup trucks and hefty trucks with rear-wheel ABS. It consists of one valve, which operates both the rear wheel and a one-speed sensor situated in the rear axle. This is fairly alike as the rear end of a three-channel system. The rear wheel is monitored together and they both have to lockup before ABS starts its action. In this system there is also the likelihood that one of the rear wheels will lock, consequences falling in brake efficiency. This system is easy to classify, typically there will be a single brake line working through a T-fitting to both rear wheels.

IMPORTANCE OF ABS Stopping Distance

The Ending distance is one of the significant

factors when it comes on behalf of braking. Ending distance is the function of

vehicle mass, its first velocity, and the braking force. Ending distance can be minimizing

by increasing in braking force (keeping all other factors constant). In all

types of road surfaces, there is always exists peaking friction. An antilock structure

can attain an all-out fictional force and results in a minimum ending distance. This

objective of antilock systems, however, is tempered by the necessity for vehicle

stability and steerability. Stability the elemental purpose of the braking system

is to decelerating and stopping of auto, maximum friction force might not be described

in some cases like asphalt and ice (p-split) surface, such significantly more braking

force is obtainable on one side of the vehicle than on the opposite side. So

when applying the full brake on both the edges will result in a yaw or skidding moment

which will tend to tug the vehicle to the high friction side and results in vehicle instability. Here comes the idea of an antilock system that upholds the

slip both rear wheels at an equal level and minimalizes two friction coefficient

points, then the lateral force is fairly high though not maximized. This donates

to constancy and is an impartial of antilock systems

Steer ability

Good peak

frictional force control is important so as to realize satisfactory lateral

forces and, therefore, satisfactory steerability. Steer ability while braking

is vital not just for minor course corrections but also for the likelihood of

steering around an obstacle. Tire characteristics play a crucial role in

the braking and steering response of a vehicle. For ABS-armed vehicles, the tire

performance is of serious implication. All braking and steering forces must be

generated within the tiny tire contact patch between the vehicle and therefore

the road. Tire traction forces also as side forces can only be produced when a

difference exists between the speed of the tire circumference and the speed of

the vehicle comparative to the road surface. This difference is denoted as a slip. It’s common to relate the tire braking force to the tire braking slip.

After the peak value has been reached, the amplified tire slip causes a decrease of the tire-road friction coefficient. ABS has to limit the slip to values below the

height value to stop the wheel from locking. Tires with a high peak friction point

achieve maximum friction at 10 to twenty slip. The best slip value reductions

as tire-road friction cuts.

CONCLUSION

With the growth in technology in automobiles, the

braking system is getting more and more progressive. Antilock brakes help

drivers to own better control of a vehicle in some road circumstances where

hard braking may be necessary. In vehicles deprived of antilock brake systems,

drivers who meeting slippery conditions have to pump their brakes to form sure

they are doing not spin out of control because of locked-up wheels. Antilock braking

system organizes wheel action with a sensor on each wheel that controls brake

pressure as necessary so that all wheels are working in an alike speed range

Comments

Post a Comment